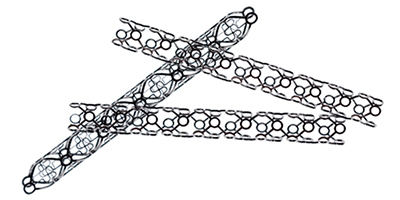

High Temperature Cooling Tube

An industrial client approached Tube Methods to fabricate high temperature cooling tubing. We began by prototyping the tubing through an exhaustive research and development process. Our final design replaced the original platinum metal with a special stainless steel material that resulted in an 80% savings.

After we arrived at the design, we put the tubing through an extensive fabrication process which included end forming, EDM wire, bending and forming. The tubing was then flattened into an oval shape and bent and drilled again, according to the customer’s specifications.

The final products had outside diameters of .252″, wall thicknesses of .020″ and lengths that ran from 4″ up to 32″. Throughout the fabrication process, we were able to hold tightest tolerances of ±.001”.

For more information about this project, please see the details below. To learn more about our other services, contact Tube Methods today.

High Temperature Cooling Tube Project Specifications

| Product Description | This high temperature cooling tube was converted from precious metal tubing with extensive fabrication and high scrap rates to a finished part made 100% by Tube Methods. This resulted in a large cost savings as well as a more consistent part. |

| Capabilities Applied/Processes | Primary Tube Drawing Tube End Forming Tube Rolling EDM Drilling Tube Bending Research & Development

Secondary Bending Flattening to Oval Shape Drilling |

| Overall Part Dimensions | Wall Thickness: .020" Length: 4" through 32" O.D.: .252" |

| Tightest Tolerance | ±.001" |

| Temperature Range | 1,600°F |

| Material Used | Tube Methods Portfolio Alloy |

| Industry for Use | Commercial/Industrial |

| Delivery Location | Worldwide |

| Standards Met | Customer Specifications |

| Product Name | High Temperature Cooling Tube |